Robotic total station layout

Pinpoint Accuracy for Construction Layouts, The Gold Standard in Precision Layout

Construction errors can cost projects 30% more in rework and delays—but precision layout eliminates that risk. At Conway Coordination and Layout Services, LLC (CCLS), we use Trimble Robotic Total Station technology to deliver unmatched accuracy and efficiency for MEP, structural, and architectural layouts.

What is Robotic Total Station Layout?

A Robotic Total Station (RTS) is an advanced surveying tool that allows single-person operation for ultra-precise layout positioning. Unlike traditional layout methods that require multiple workers, RTS uses laser-guided automation to streamline the process, eliminate errors, and improve efficiency.

Robotic Total Station Layout Applications

We specialize in Robotic Total Station layout for various construction needs, including:

-

MEP Layout & Coordination

Ensuring mechanical, electrical, and plumbing (MEP) systems are positioned exactly as designed. -

Structural & Architectural Layout

Precise layout of walls, columns, beams, and other structural elements. -

Overhead Hanger & Penetration Placement

Accurate placement of hanger supports, ductwork, and penetrations for streamlined installations. -

Anchor Bolt Verification & Positioning

Ensuring anchor bolts are set exactly where they should be, preventing costly rework. -

Concrete & Foundation Layout

Precise layout for footings, foundations, and slabs, ensuring they are aligned perfectly with structural plans.

By leveraging advanced positioning technology, we help you reduce costly rework, maintain efficiency, and keep your project on schedule.

Why Choose Robotic Total Station Layout?

Pinpoint Accuracy

Reduces human error and ensures exact placement.

Increased Productivity

Faster than traditional methods, allowing crews to work efficiently.

Single-Person Operation

Minimizes labor costs while maximizing precision.

Seamless BIM Integration

Aligns perfectly with 3D models and VDC workflows.

Reduced Rework & Cost Savings

Precision layout prevents costly mistakes and delays.

Let’s Build with Precision.

Contact Us Today!

How Robotic Total Station Layout Works

Step 1: Site Setup & Calibration

We establish control points using surveyor data or predefined benchmarks, ensuring accurate alignment from the start.

Step 2: Digital Layout & Positioning

Our Trimble RTS system reads BIM models, project drawings, or CAD files and projects exact coordinates onto the field.

Step 3: Verification & Adjustments

We cross-check all measurements, confirm alignment, and adjust as needed before teams begin construction.

Step 4: Handoff & Documentation

Once layout is complete, we provide detailed digital reports and verification data, ensuring everything is positioned correctly.

Industries We Serve

CCLS provides Robotic Total Station layout services for:

Commercial Construction

Industrial Facilities

Healthcare & Pharmaceuticals

Residential & Mixed-Use Projects

Frequently Asked Questions

How accurate is Robotic Total Station layout?

Our Trimble RTS technology provides millimeter-level accuracy, ensuring that every component is placed exactly where it needs to be.

Can RTS layout be used on all types of projects?

Yes! We provide layout services for commercial, industrial, and residential projects, ensuring precision across all sectors.

What is the difference between RTS layout and traditional layout methods?

Unlike traditional layout that requires multiple workers, RTS allows for single-person, fully automated positioning, reducing labor and minimizing human error.

How does RTS layout integrate with BIM and VDC workflows?

Our RTS system syncs directly with BIM models and CAD files, ensuring a seamless transition from digital plans to real-world execution.

How do I schedule a Robotic Total Station layout service?

Call us at +1 (843) 283-4618 or email [email protected] to book your consultation!

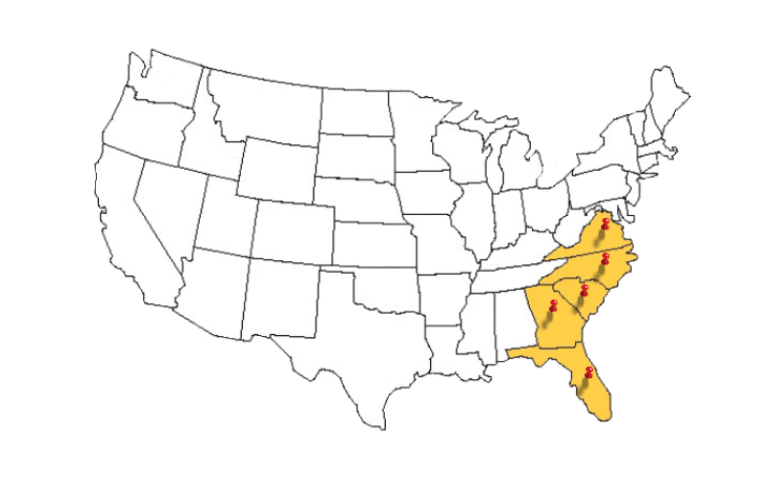

Serving the Southeastern U.S. & Beyond

- South Carolina

- North Carolina

- Virginia

- Florida

- Georgia